The insert you should choose depends on your application. Below are five inserts and the applications that best match.

|

1. Epoxied-In InsertsThe epoxied-in inserts are designed for installation in wood, aluminum, soft metals, plastics and fiberglass. Dependent on individual insert, epoxied-in inserts are available in brass, aluminum, stainless steel, and plated steel. |

|

2. Pressed-In InsertsPressed-in inserts work well for wood, aluminum, soft metals, plastics, and fiberglass. While application for pressed-in inserts is the same as epoxied-in inserts, pressed-in inserts have the easiest installation method. Depending on your project and time, pressed-in inserts may be the best option for you. This specific type of insert is available in brass, aluminum, and plated steel. |

|

3. Molded-In InsertsWorking with plastics, rubber, or ceramics? We recommend our molded-in inserts. These are available in brass, aluminum and stainless steel depending on the select product. |

|

4. Self-Tapping InsertsIf you’re looking for chip-free installation and superior holding power, self-tapping inserts are likely the best bet. These inserts work best in wood, particleboard, ABS and soft metals. Their unique holding power makes them a great fit for vehicles, marine equipment, military applications, plant and equipment construction and other heavy machinery and appliances. These inserts are available in brass, plated steel, diecast, and stainless steel. |

|

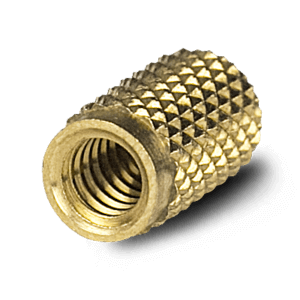

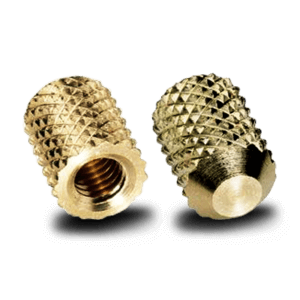

5. Ultrasonic and Thermal InsertsThe specially designed Ultrasonic and Thermal inserts that we offer have superior holding power in ABS, polycarbonates, thermoset plastic and thermoplastics. This insert is ideal for automatic, high production operations and is available in brass, plated steel and stainless steel. |

If you are already using an insert and looking for a comparable product from Yardley Inserts, download our Insert Comparison Chart. If you are looking for a custom solution, we produce a wide variety of automatic screw machine parts for the aerospace, appliance, automotive, defense, electronics and other industries.

Give us your requirements and the problems that you are trying to solve. Our engineers will determine the most efficient and cost-effective method for producing quantities from prototype to a million pieces or more.